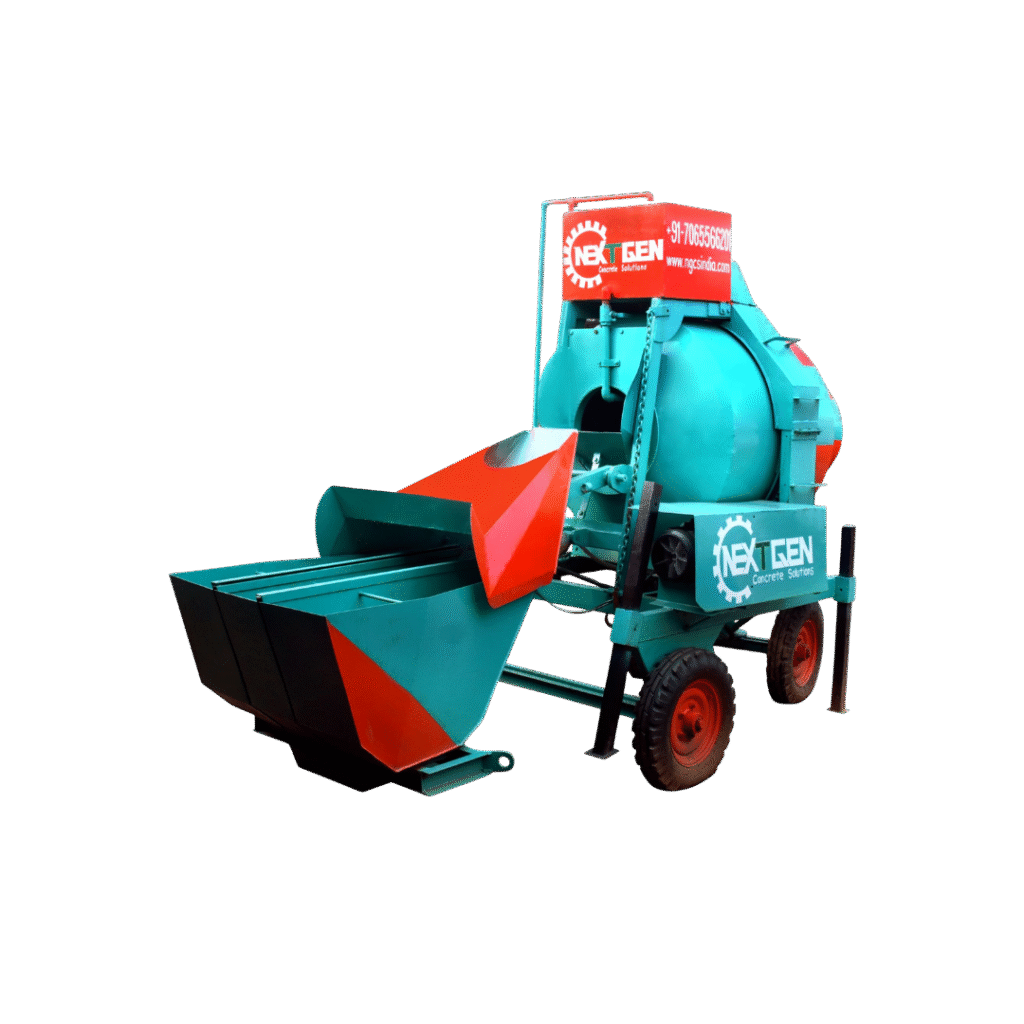

REVERSIBLE MOBILE CONCRETE BATCHING PLANT

NextGen RM800/1050 Concrete Mixer | manufacturer & exporter of reversible concrete drum mixer rm 800/1050 | mini mobile batching plant | mobile concrete mixer batching machine | ready mix concrete from INDIA | batching machine | concrete mixing | mini mobile batching plant | reversible concrete mixer RM 800/1050 INDIA. Reversible concrete mixer machine or Mini concrete mobile batching plant is widely used in construction industry. It is the reversible concrete drum mixer, available in single bin, two bin and three bin & multi bin models. Leading Construction Company in India wants a full proof and safe reversible drum mixer. These reversible drum mixers from NextGen Concrete Solution also prevent the wastage of water, fulfilling the responsibility towards environment.

The reversible drum mixers required by leading construction companies, are of various types, available with NextGen. These can be classified based on the number of bins and based on the mode of operation.

NextGen India is committed to offer a wide assortment of Reversible Drum Mixer to cater the diverse demands of its clients. A widely used machine in the construction industry is the reversible drum concrete mixer, available in single bin, two bin and multi bin models.Any leading construction company in India wants a full proof and safe reversible drum mixer. These reversible drum mixers from NextGen also prevent the wastage of water, fulfilling the responsibility towards environment.

Reversible drum mixers from NextGen, one of the well known construction equipment supplier, are specialized construction equipment used to mix the concrete of cement, sand and other aggregates and carry the same from the batching plant to the area where it has to be poured.

Benefits

► It enables smooth mixing

► Manufactured with high quality raw materials

► Time saving high capacity mixing drum

► The operational system of the machine is silent and hence produces very little noise

► It requires very low maintenance

► It is portable because of its compact design and can be easily carried to the construction sites

► It does not produce any concrete dust and thus the environment remains clean

► Diesel reversible concrete mixer is best used for remote sites, where there is no electricity

► Undergo several quality tests

► Heavy duty, balanced chassis

► Overflow water management system

► Electronic load cell system

► Single, double and three bins

► Diesel reversible drum concrete mixer

► Electric reversible drum concrete mixer

Technical Specification of Reversible Mobile Concrete Batching Plant

| Model No. | NGRM – 800 | NGRM – 1050 |

|---|---|---|

| Output Capacity | 8-10 cum/hr. | 12-15 cum/hr. |

| Load Capacity | 750 Ltr. | 1050 Ltr. |

| Batch Capacity | 500 Ltr. | 750 Ltr. |

| Chassis | Heavy Duty, Rebust& Balanced Chassis | Heavy Duty, Rebust& Balanced Chassis |

| Jack Leveling | Pin Type Jack (04 Nos.) | Pin Type Jack (04 Nos.) |

| Bin Type | Three Bin | Three Bin |

| Prime Mover | 10HP 3 Phase Motor | 12.5HP 3 Phase Motor |

| Hopper Jack | Liftwell Hydraulic Jack | Liftwell Hydraulic Jack |

| Mixing Drum | Forward Rotation Mixing of Concrete & Reverse Rotation Discharge of Concrete | Forward Rotation Mixing of Concrete & Reverse Rotation Discharge of Concrete |

| Weighing System | Load Cell Based Weighing System with Digital Display | Load Cell Based Weighing System for Higher Accuracy |

| Water Tank | 200 Ltr. Capacity | 250 Ltr. Capacity |

| Water Feeding | Through 1HP Motor Pump | 1 HP Self Priming Monoset Pump |

| Material Feeding | Through Hydraulic Operated Hopper | Through Hydraulic Operated Hopper |

| Vibratory System | Optional | Optional |

| Voltage Supply | 3 phase, 415 volts, 50 Hz | 3 phase, 415 volts, 50 Hz |

| Towing Speed & Sys. | Tow bar is provided for towing and speed is 20 km /hour | Tow bar is provided for towing and speed is 20 km /hour |

| Control Panel | Microprocessor Based Control Panel with Internal Cabling | Microprocessor Based Control Panel with Internal Cabling |

| Gear Ring & Roller | Accurately Machined with Gear Cutting Operation | Accurately Machined with Gear Cutting Operation |

| Lubrication System | Lubrication pump in built for lubricating rollers | Lubrication pump in built for lubricating rollers |